In an era where technological innovation is redefining the boundaries of industry, Boston Dynamics reveals a new facet of its iconic humanoid robot, Atlas. Far from the acrobatic demonstrations that amazed the public, a forty-minute technical video unveils how Atlas is now establishing itself as an industrial operator capable of mastering a complex factory environment with unprecedented precision and adaptability. Atlas’s performance is no longer limited to the simple execution of programmed tasks but relies on robust intelligence capable of learning, adapting, and reacting in real time to production contingencies.

This significant turning point raises many questions around automation in modern industries. While traditional robotic arms and other automated platforms already manage a large share of operations, the introduction of such a flexible humanoid robot represents a revolution for some, a source of concern for others. Boston Dynamics directly addresses these doubts by reaffirming that the key lies in versatility and not just specialization, thus accelerating industrial processes that were previously hindered by the rigidity of traditional systems.

- 1 Atlas, an industrial robot serving flexibility in the factory

- 2 Atlas’s learning techniques to master the industrial environment

- 3 A well-thought software architecture for optimal control in industrial settings

- 4 Economic and industrial impact of Atlas in modern factories

- 5 Technical and human challenges related to Atlas’s factory integration

- 6 Atlas and the revolution of intelligent automation in 2025

- 7 Future prospects for Atlas and industrial robotics

Atlas, an industrial robot serving flexibility in the factory

For years, the integration of humanoid robots in factories has been the subject of technical and economic debates. Robotic arms and mobile platforms dominate the industrial landscape because their efficiency, robustness, and controlled cost meet the majority of needs. However, in factories where flexibility is paramount, especially in automotive manufacturing, these systems show their limits.

Boston Dynamics points out that the real issue does not lie in technical complexity but rather in the cost and adaptation delays. Highly flexible production lines require frequent reconfiguration, which currently results in colossal investments in engineering and time. For example, assembling vehicles with thousands of variants on the same line often requires creating dedicated robots, with a design cycle that can last more than a year and cost several million dollars.

It is in this context that Atlas’s bet makes perfect sense. Rather than designing a machine specialized by task, Boston Dynamics offers a robot capable of quickly switching missions through software reprogramming and adaptation by learning. This strategy injects new flexibility into factories, drastically reducing the implementation time for new operations to just a few days. Through this approach, Atlas meets the growing needs of an industry that must innovate at an unprecedented speed while maintaining high standards of quality and safety.

Atlas’s learning techniques to master the industrial environment

To achieve this level of adaptability, Boston Dynamics relies on a learning methodology combining several complementary approaches. Unlike traditional robots coded line by line for each movement, Atlas acquires its skills through an artificial intelligence system capable of assimilating new experiences and generalizing them.

The first method is based on teleoperation assisted by virtual reality. A human operator guides Atlas’s movements, translating precise and contextual actions into training data. This information serves as a basis for the robot to reproduce and improve these movements autonomously, ensuring execution precision adapted to the variability of industrial tasks.

A second method exploits the power of massive virtual simulations. Atlas is subjected to millions of simulated scenarios where it must react to complex situations or perform very dynamic and precise gestures, such as moving engine hoods or adjusting delicate parts. This phase refines its performance while avoiding risks linked to repeated physical tests.

Finally, Boston Dynamics also prepares Atlas to learn by observation. By analyzing vast databases of videos showing human operators in real situations, the robot develops new intuition, integrating subtle nuances of human gestures to optimize its own precision and efficiency. This form of learning by observation opens fascinating prospects for the robot’s versatility in an industrial context in constant evolution.

List of Atlas’s learning methods in the factory:

- Virtual reality teleoperation: human guidance for precise gesture acquisition.

- Digital simulation: large-scale virtual training to accelerate learning and test complex actions.

- Learning by observation: video analysis of operators to develop a fine understanding of industrial gestures.

A well-thought software architecture for optimal control in industrial settings

Boston Dynamics departs from the classical model of total artificial intelligence controlling all of Atlas’s movements. This so-called “pixels-to-motors” technique, where AI learns to react bluntly to visual perceptions, proves too unstable for industrial requirements, where safety and precision are paramount.

For this reason, Atlas benefits from a layered architecture divided according to distinct functions. A so-called decision layer focuses on scene understanding and intention planning, such as selecting where to place a foot or how to orient a hand. Then, an execution layer is responsible for balance control, fine motor coordination, and mechanical constraint management.

This differentiation enhances robustness, reliability, and reaction speed. This modular organization echoes the functioning of human motor control, where cortical decisions are immediately translated into adjustments by the body mechanics. In practice, this architecture ensures smooth and precise movements for Atlas, even in very dynamic factory contexts.

| Function | Role | Advantage |

|---|---|---|

| Decision layer | Scene analysis and movement planning | Intellectual flexibility and abstract task management |

| Execution layer | Motor control, balance, and mechanical constraints | Precision, stability, and speed |

| Human-machine interface | Communication with operators and teleoperation | Adaptability and continuous learning |

Economic and industrial impact of Atlas in modern factories

The introduction of humanoid robots like Atlas into production lines marks a major evolution in the industrial landscape. The main gain comes from flexible automation, in contrast to often rigid and specialized systems on which industries have depended for decades. With Atlas, companies can consider shorter production cycles capable of quickly adapting to changing market demands.

Take for example an automotive assembly plant that must produce several models with thousands of variants. Integrating Atlas would significantly reduce machine reconfiguration times, avoiding costly breaks in the production line. Furthermore, the robot’s flexibility reduces the need for investments in specific equipment, particularly for one-off or seasonal tasks.

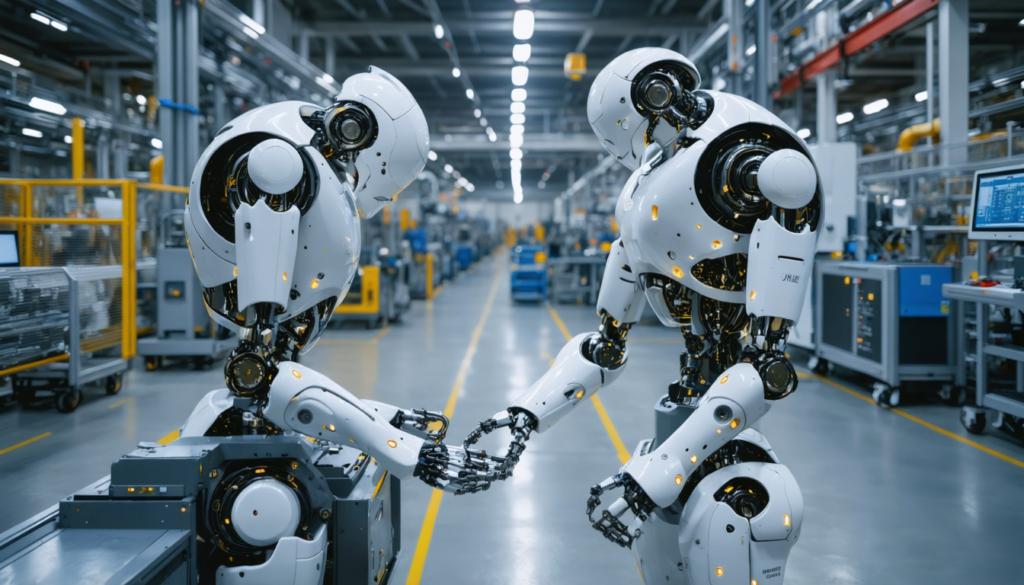

The strategic partnership between Boston Dynamics and Hyundai Motor perfectly illustrates this dynamic. Together, they are rethinking industrial processes to include humanoid robots as fundamental elements of the production line. This collaboration paves the way for intelligent automation that is more responsive and capable of integrating delicate or variable human tasks.

Despite spectacular advances, several challenges remain in the large-scale deployment of Atlas in industrial settings. First, technical complexity remains high. The robot must not only manage dynamic balance but also interact with varied objects, often in confined spaces and in the presence of humans. This context requires exceptional reliability to avoid any accident or incident.

Next, integrating a humanoid robot deeply modifies work environments. Employees must learn to collaborate with these machines, which implies changes in corporate culture, training, and workstation design. Trust in technology is a key factor. Boston Dynamics is thus working to develop intuitive interfaces to facilitate this coexistence between humans and machines.

Moreover, acquisition and maintenance costs remain high, although amortizable thanks to Atlas’s versatility. Companies therefore need to find the right balance between initial investment and return on investment over time, also considering potential gains in quality, safety, and flexibility.

Atlas and the revolution of intelligent automation in 2025

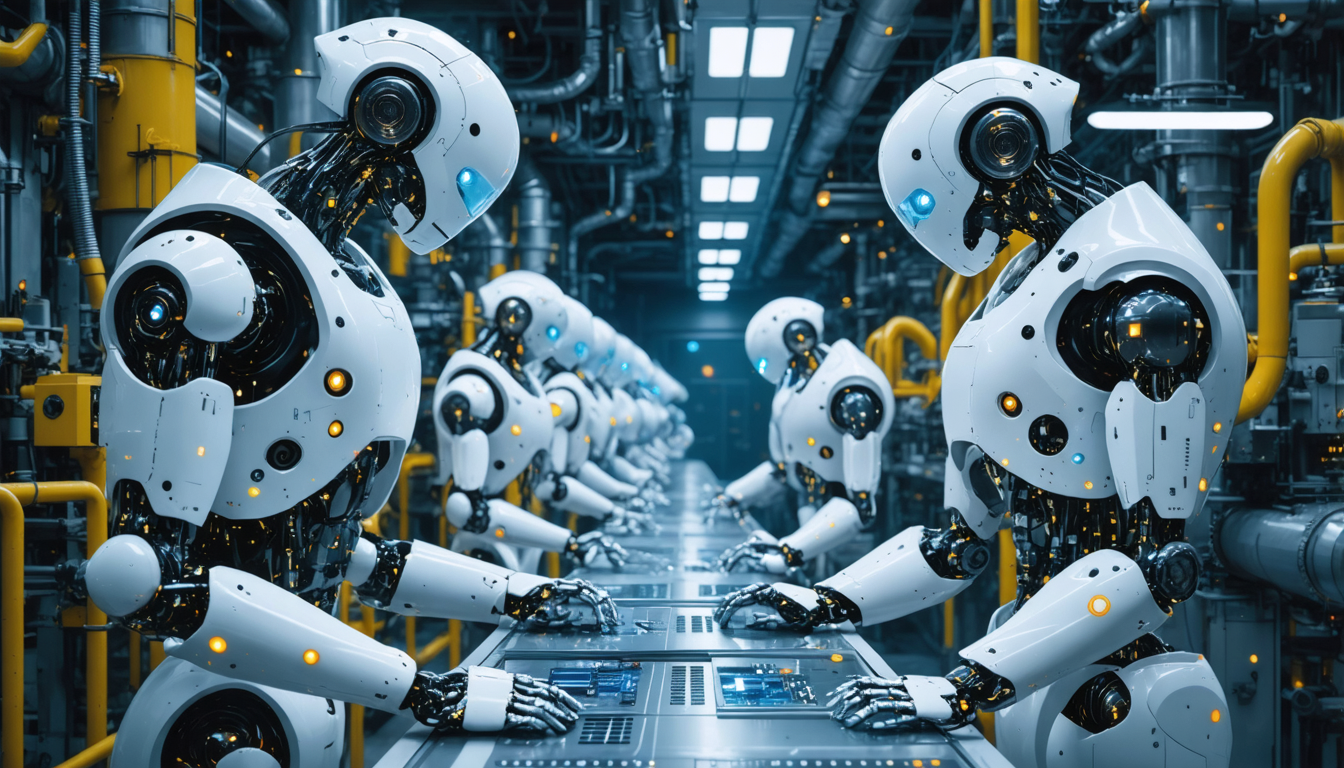

In 2025, industry finds itself at the crossroads between traditional automation methods and the emergence of ultra-adaptive intelligent solutions. Atlas embodies this revolution by surpassing the usual constraints of industrial robots. Equipped with intelligence capable of continuous learning, it can be quickly reprogrammed to take on new functions without requiring a complete overhaul of the equipment.

This ability opens unprecedented prospects for multitasking factory management, where changing demand requires rapid reconfiguration of robotic tasks. Unlike the rigid model that still largely dominates production sites, Atlas allows a true fusion between the power of machines and human flexibility. This hybrid model could become the norm in the coming years, thus transforming the way we envision industrial production.

Future prospects for Atlas and industrial robotics

The advances made with Atlas show that the future of industrial robotics will necessarily be marked by humanoid machines capable of rapid adaptation and evolutionary learning. Their contribution is not limited to increasing production speed but also offers improved quality and precision while enhancing workplace safety.

Facing the growing demands of industries, it is likely that we will see a gradual integration of Atlas across various sectors, ranging from automotive to electronics, including the assembly of complex machinery. Future factories will thus be hybrid environments where humans and robots coexist and collaborate closely, each benefiting from the strengths of the other.

Finally, learning by observation and simulation could pave the way for robots capable of nearly autonomous self-improvement, further reducing the need for human assistance. The technological innovation brought by Boston Dynamics already offers a glimpse of this profound transformation, whose impacts are expected to revolutionize the industrial sector in the years to come.