While technological advances in the field of robotics may seem impressive at first glance, the industry is facing growing disillusionment in 2026. Robots, whether industrial or humanoid, still struggle to meet the high expectations placed on them. This significant gap between the hype and the technical reality fosters an atmosphere of distrust and frustration among consumers and businesses alike. Promising innovations, such as those presented by major figures like Elon Musk or pioneering startups, do not always translate into reliable performance in the field. This situation results in stagnant sales, rapidly abandoned products, and a significant ecological risk due to the accumulation of unused electronic waste.

At the humanoid summit held in Mountain View, the truth was revealed without concession: today’s robots, despite their futuristic appearance and sometimes impressive demonstration capabilities, remain far from being able to assist humans universally and effectively. Experts also warn of the dangers of too rapid commercialization, which could lead to lasting loss of trust in the sector. Here, robotics is progressing not only under the banner of innovation but also under the weight of technical difficulties and growing disappointment in a market full of promises.

- 1 Major technical challenges hindering the performance of modern robots

- 2 The impact of technological disillusionment on the global robotics industry

- 3 The complexity of intelligent automation: a challenge yet to be met

- 4 The illusions of the humanoid market: promises and realities

- 5 The real costs of robotization: a fallible view on investment

- 6 Targeted uses to improve reliability and meet real needs

- 7 Towards better maturity thanks to progressive and sustainable innovation

Major technical challenges hindering the performance of modern robots

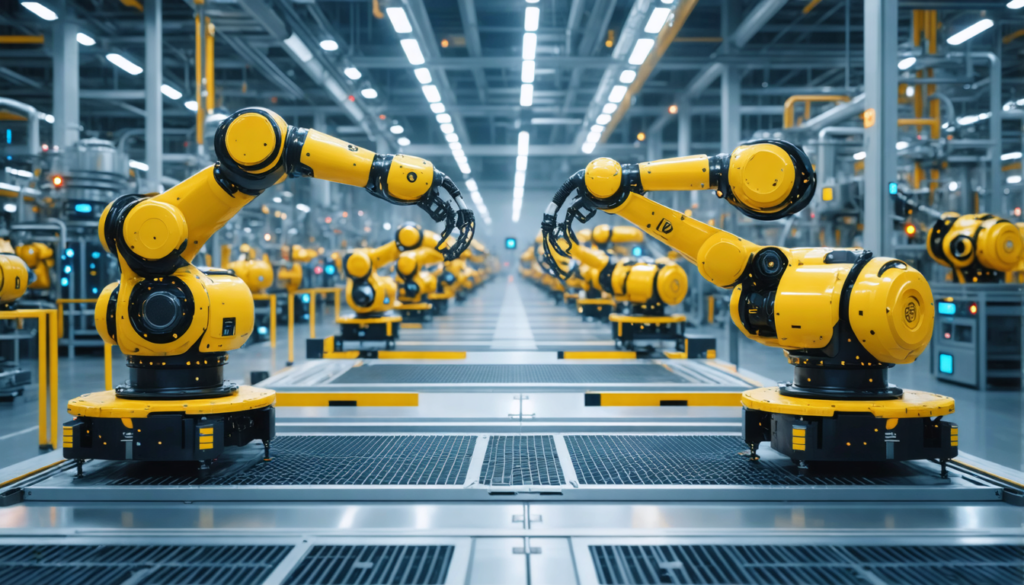

The performance of robots, although often praised in the media and technology fairs, still faces many complex technical obstacles. The main challenge lies in making a robot reliable and autonomous in varied and unpredictable environments. Unlike the highly structured assembly lines in industry, humanoid robots must be able to analyze situations in real time, interpret diverse data, and act appropriately. This combination of perception, decision-making, and execution remains a considerable challenge.

For example, a robot designed to fold laundry at home requires a very high level of motor coordination finesse and a precise understanding of fabrics, shapes, and constraints. Currently, these machines often limit themselves to performing basic mechanical gestures but cannot compete with human flexibility and adaptability. Kaan Dogrusoz, founder of Weave Robotics, compares these robots to the first laptops of the 1990s: promising, but still too limited to revolutionize their field.

This comparison recalls the Apple Newton, a product with oversized ambitions launched in the 1990s, but which encountered numerous technical flaws and a lack of technological maturity. The enthusiasm generated by modern robotics could face a similar fate if developments do not follow a realistic pace. Beyond gestures and perception, communication between the robot and the user also poses a problem. The interface must be intuitive and reliable because poor interaction can quickly turn an aid tool into a source of errors and risks.

Component reliability is another obstacle. Robots incorporate a multitude of sensors, motors, and sensitive electronic modules, often prone to failures in demanding industrial or domestic environments. These failures increase maintenance costs and undermine user trust. This is even more sensitive in high-risk scenarios where safety must be strictly ensured. Ani Kelkar, an expert at McKinsey, specifies that for every investment in the robotic machine itself, the majority of expenses is dedicated to accident prevention, thus highlighting the complexity of their implementation.

The impact of technological disillusionment on the global robotics industry

The gap between expectations and the actual capabilities of robots affects the entire robotics industry. On the commercial level, sales of industrial robots stagnate or decline in several regions, notably in France, where the post-health crisis enthusiasm has given way to a pronounced slowdown. Companies now hesitate to invest massively, fearing disappointing returns or rapid obsolescence of the machines.

This caution is also due to the complexity of integrating robots within production lines. A high-performing robot alone is not enough to guarantee successful automation: deployment also requires rethinking processes, training teams, and ensuring constant maintenance. In practice, a well-calibrated robot for a specific task can prove unusable in a context where needs evolve rapidly. The example of certain automated lines in the automotive industry shows that robots with rigid controls cannot suffice when faced with significant product or flow variations.

Furthermore, a too optimistic navigation toward domestic robots — supposed to become omnipresent assistants — faces both the complexity of tasks to be executed and often prohibitive prices. The promise of an assistant capable of autonomously managing the home has met a much more prosaic and technical reality. Robots capable of performing a task like folding laundry without supervision remain rare and generally limited to very controlled demonstrations.

From an ecological perspective, this disillusionment leads to a worrying accumulation of electronic waste. The rushed market launch of prototypes, often sold at high prices with preorders, results in poorly performing products quickly abandoned. Chinese authorities have sounded the alarm, warning that uncontrolled sector development could generate a mountain of useless electronic waste, both costly to recycle and polluting.

The complexity of intelligent automation: a challenge yet to be met

The transformation of the industry through automation relies on integrating intelligent robotic systems capable not only of executing physical tasks but also of learning, anticipating, and adapting autonomously. However, the artificial intelligence integrated into robots remains insufficient in many cases to manage this complexity. Deep learning, object recognition, and real-time planning are progressing but struggle to reach the desired robustness.

Robots must be able to operate in dynamic environments where variables and unpredictabilities are the norm. However, current algorithms do not always allow optimal decision-making and fully satisfactory error management. For example, a robot tasked with assembling a part must be able to immediately detect any defect or anomaly without stopping the entire line, which remains difficult to achieve fully. This slows the widespread adoption of integrated robotic solutions in so-called “smart” factories.

Moreover, interaction between multiple robot-automata in a coordinated system remains a difficult issue. Optimizing communication and cooperation between machines to improve the efficiency of the industrial system is an ongoing research topic, and several projects suffer from operational delays.

Safety is also a crucial pillar. Every automated system must guarantee perfect safety for human operators and increased resistance to failures. The cost of these measures significantly inflates projects, limiting access to this technology to a restricted circle of industrial players. Ani Kelkar emphasizes this well: most of the costs do not go to the machine but to securing its environment and associated training.

The illusions of the humanoid market: promises and realities

Humanoid robots have raised particular fascination for decades, fueling dreams of personal assistants, life companions, or domestic automatons. Yet, the contrasting reality of 2026 reveals a significant gap between expectations and current performance. Despite the media coverage of impressive prototypes, these devices are generally incapable of handling complex everyday tasks.

Preorders costing tens of thousands of dollars, often made on the strength of spectacular videos, have not been enough to guarantee customer satisfaction. Like the Apple Newton, these robots also generate strong skepticism regarding their commercial and technological viability. The risk of a “bubble” effect is real, threatening the very image of the robotics sector.

Kaan Dogrusoz mentions this comparison to warn: current humanoids are still “at the prototype stage,” a fragile product far from optimized for a domestic or mass commercial use. This situation urges industry experts to recommend caution and advise avoiding the purchase of such robots in their current forms, at least until the technology reaches a higher level.

Companies, although attracted by the idea of versatile robots, realize that development efforts must focus on specific and controlled applications. This more pragmatic approach allows for obtaining industrial robots capable of handling heavy loads, performing repetitive tasks, and improving overall productivity without compromising reliability.

The real costs of robotization: a fallible view on investment

Beyond technical aspects, the financial question is a key factor in the difficulty faced by the robotics industry. Investing in a robot, whether industrial or humanoid, is not limited to purchasing the machine. As Ani Kelkar from McKinsey pointed out, for every dollar invested in the machine itself, four other dollars are often needed to ensure safety, training, integration into existing systems, and maintenance.

This complex cost structure deters many companies, especially SMEs, from massively adopting robotic technologies. Robotics is often seen as a luxury reserved for large industries with substantial resources to manage risks. Moreover, disappointments caused by robots unsuitable for the intended tasks heighten reluctance to invest in this field.

A summary table illustrates the main expense items related to implementing an industrial robot:

| Expense Item | Percentage of Total Cost | Description |

|---|---|---|

| Robot purchase | 20% | Initial cost of the machine and associated software |

| Installation and integration | 25% | Adaptation of infrastructure and process coding |

| Team training | 15% | Teaching the necessary new skills |

| Maintenance and safety | 30% | Monitoring operations, accident prevention |

| Other miscellaneous expenses | 10% | Managing unforeseen events, software updates |

This breakdown emphasizes that beyond the technological aspect, robotization requires a global strategy that goes beyond the simple acquisition of equipment and integrates all indirect costs. An ill-considered investment, based solely on displayed innovation, can quickly lead to economic disillusionment.

Targeted uses to improve reliability and meet real needs

Faced with these difficulties, some companies now favor robotic solutions targeted at well-defined functions. These pragmatic choices allow obtaining concrete results more quickly and improve the overall reliability of machines. For example, in the food industry, automating cutting or packaging relieves operators of repetitive and tedious tasks while complying with strict sanitary standards.

In the pharmaceutical industry, robots assist with batch preparation and quality control with precision superior to manual work. Such specific uses reduce error risks and optimize productivity. This refocusing on essentials tends to regain the trust of economic actors, tired of overly broad promises and still imperfect prototypes.

In this sense, Industry 4.0 retains its transformational potential but with a gentler, more realistic progression. Intelligent automation is now built on a solid and proven base, avoiding media hype that leads to major disappointments.

- Automation in targeted production lines

- Collaborative robots to assist operators

- Predictive maintenance facilitated by advanced sensors

- Gradual integration of AI for specific tasks

- Continuous training to accompany technological evolution

Towards better maturity thanks to progressive and sustainable innovation

For robotics to finally overcome current difficulties and limit persistent disappointment, it is necessary to adopt a strategy centered on progressive innovation. This path involves continuous strengthening of research and development, but also rigorous evaluation at each production stage.

Careful monitoring of robots’ actual performance under usage conditions, coupled with ongoing dialogue with users, allows adapting and improving models. This pragmatic method contrasts with the temptation to announce technological revolutions before the technology is truly ready.

Companies must thus bet on robust technologies, simplified maintenance, and increased customization. This work of maturation, though less spectacular, guarantees renewed credibility and better integration of robots in industry and beyond. Strengthened collaborations between research laboratories, startups, industrial players, and regulatory authorities are essential to balance innovation, economy, and sustainability.