In a world where technology and industry evolve at a rapid pace, it is essential to understand the key role played by certain companies in the manufacturing of the products we use daily. Among these players, the OEM holds a major strategic position. Its acronym, often encountered without real explanation, covers a complex and fundamental reality: that of an Original Equipment Manufacturer that shapes essential components for numerous international brands. Whether in computing, the automotive industry, or even in the consumer electronics sector, the OEM greatly influences the quality, production, and assembly of final products. At a time when the global supply chain is becoming more complex and environmental standards are intensifying, deciphering the exact functioning of the OEM becomes a necessity for both professionals and informed consumers.

This analysis will delve into the precise definition of the OEM, its mode of operation, and the challenges it carries in modern industries. We will also discover how this model has adapted to the new economic and ecological constraints of 2025, notably through strategies of alliances and innovations. Furthermore, by differentiating these players from ODM manufacturers and the secondary market, we will clarify the practical aspects that influence both the quality and the price of the products we hold in our hands. This overview will offer a nuanced understanding of the backstage of current industrial production, which largely relies on this multi-sector Original Equipment Manufacturer system.

- 1 Understanding the Definition and Fundamental Role of the OEM in Modern Industry

- 2 Detailed Analysis of the Industrial Operation of OEMs: From Production to Marketing

- 3 Differences Between OEM, ODM, and Other Players: An Essential Mapping to Understand the Industrial Chain

- 4 Economic and Industrial Advantages of Working with an OEM: Optimization and Shared Expertise

- 5 Transformation of OEM Strategies Facing New Environmental Regulations and Technological Innovations

Understanding the Definition and Fundamental Role of the OEM in Modern Industry

The acronym OEM stands for “Original Equipment Manufacturer,” in French, “fabricant d’équipement d’origine.” In its simplest form, it designates a company that designs and manufactures components, parts, or even complete products intended for other companies. These companies then market these goods under their own brand, thus integrating OEM elements into their final offering. This interaction is at the heart of industrial functioning in several key sectors.

For example, a computer brand such as Lenovo or Dell contains many components from specialized OEMs. Certain essential parts such as the processor, memory, or graphics cards are produced by leading companies in their field and then assembled in the final manufacturer’s factories. Fundamentally, this allows these brands to focus on design, sales, and after-sales service, while the specialized technical expertise and production are delegated.

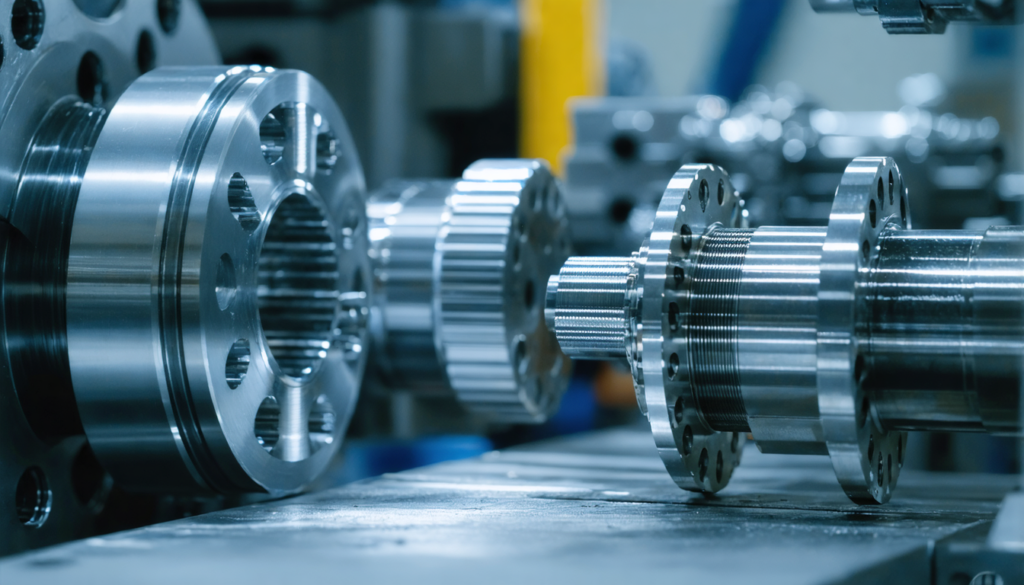

In the automotive sector, a similar dynamic is observed. Engine parts, embedded electronic systems, or touch screens often come from OEMs. These equipment manufacturers bring their know-how in a specific domain, guarantee the quality of components, and enable manufacturers to accelerate time-to-market. The high-tech subcontracting system thus forms the basis of a resilient, efficient, and less costly production chain.

In summary, the OEM is an essential bridge between industrial design and the marketing of goods. It provides intermediate or complete products that another brand adapts or resells. It is a model that combines flexibility and quality, strongly structuring manufacturing on a global scale today.

Detailed Analysis of the Industrial Operation of OEMs: From Production to Marketing

The operation of an Original Equipment Manufacturer is based on several crucial stages that guarantee both quality and efficiency. It all starts with the design or manufacturing of components according to specifications provided by clients or the company’s own technical expertise. This point is decisive because, unlike a simple subcontractor, the OEM controls the complete production chain, from development to industrial series output.

Once the prototype is validated, the OEM launches industrial production in large batches. These volumes then allow cost optimization related to materials, labor, and stock management. Using an OEM thus allows client companies to avoid massive investments in manufacturing infrastructure, which significantly reduces overall production costs.

On the commercial side, the OEM model offers interesting leeway to companies that purchase these components or products. They can choose to integrate these parts into complete systems under their own logo or to market these equipments in modular or standardized form. This is especially common in computing, where manufacturers sell assembled computers with OEM components supplied by third parties.

Here are the main phases of OEM operation in the industry:

- Technical design: Drawing up plans or adapting products to the specific needs of the client.

- Industrial manufacturing: Mass production of components according to high-quality standards.

- Quality control: Rigorous inspection to ensure conformity and reliability.

- Distribution and integration: Delivery to final manufacturers for assembly or resale.

This model, which combines specialization and delegation, ensures better responsiveness to market changes. It also allows leveraging the sharp skills of expert equipment manufacturers, particularly in complex technical fields such as embedded electronics or innovative materials.

Differences Between OEM, ODM, and Other Players: An Essential Mapping to Understand the Industrial Chain

Although OEM is a commonly used term, it is important to clearly distinguish it from other close concepts such as ODM (Original Design Manufacturer) and the secondary market. These distinctions are crucial to apprehend production modes and implications in terms of quality, intellectual property, and economic model.

Original Equipment Manufacturer (OEM) vs Original Design Manufacturer (ODM)

While the OEM manufactures according to established specifications, often created by its clients, the ODM goes further. The ODM fully designs products according to its own expertise, which are then sold to other brands. These brands market them under their own name without having participated in the initial development. This operating method provides an economic advantage, especially regarding costs, because the ODM pools design and manufacturing.

For example, in the smartphone field, some manufacturers use ODM products that they rebrand for distribution, whereas others order specific parts from OEMs to assemble a customized final product. This distinction also influences the nature of the partnership and responsibilities in case of defects or technical problems.

OEM products vs secondary market

Another frequent contrast concerns OEM products compared to those from the secondary market. Secondary market products are parts or components offered by companies not linked to the original manufacturers, often less expensive but potentially less reliable. These spare parts may be compatible but are not guaranteed by OEMs, which can pose risks for durability and equipment performance.

OEM manufacturers and Value-Added Resellers (VAR)

Furthermore, value-added resellers play a particular role by offering clients OEM products enriched with additional functionalities or services. This collaboration between OEMs and VARs allows responding to specific needs in targeted market segments while relying on the quality and reliability of original components.

| Category | Main Role | Design Responsibility | Example | Cost |

|---|---|---|---|---|

| OEM | Manufacturing according to client specifications | Designed by client | Intel process in computers | Moderate |

| ODM | Design and manufacture | Under ODM responsibility | Generic smartphones sold by several brands | Lower |

| Secondary market | Manufacturing compatible spare parts | Independent | Unofficial spare parts | Low |

| VAR | Addition of features to OEM products | Designed by OEM and VAR | Additional integrated software | Variable |

Collaborating with an Original Equipment Manufacturer presents several major benefits for companies, both economically and technologically. First of all, prioritizing an OEM allows significant optimization of production costs thanks to economies of scale. Producing in large series reduces the unit price of components, making final products more competitive in the market.

Next, the experience and specialization of OEMs offer a guarantee of high quality. These manufacturers often have cutting-edge technologies and exclusive processes that are not always accessible to client brands. For example, a computer manufacturer relying on a recognized OEM for its processors can guarantee better performance and better durability for its products.

Moreover, outsourcing production to an OEM allows companies to focus their resources on their core business — marketing, distribution, design, or after-sales service — while ensuring manufacturing is in good hands. This sharing of responsibility can also shorten the development cycle, accelerating the arrival of innovations on the market.

Here is a list of key advantages of working with an OEM:

- Reduction of manufacturing costs thanks to volume production.

- Access to technical expertise and specific innovations.

- Better management of deadlines and flexibility in orders.

- Quality improvement thanks to rigorous controls.

- Focus on commercial strategies rather than production.

By combining these assets, the OEM not only optimizes the industrial chain but also strengthens the overall competitiveness of partner companies.

Transformation of OEM Strategies Facing New Environmental Regulations and Technological Innovations

The industrial context in 2025 is strongly marked by environmental imperatives, particularly in the automotive sector. The CAFE (Corporate Average Fuel Economy) standard adopted by the European Union imposes strict ceilings on the average CO₂ emissions of new vehicles. This policy heavily constrains manufacturers and their OEM partners to review their production chains and product portfolios.

In response to these demands, OEMs specializing in automotive parts must adapt to provide components suitable for cleaner and more efficient powertrains. This means an increase in technologies related to batteries, embedded electronics, but also the lightening of materials to reduce vehicle weight. For example, several strategic alliances emerged in 2025 between European manufacturers and suppliers of solid-state batteries or recyclable materials.

The target is clear: to avoid heavy financial penalties, OEMs must support manufacturers in producing hybrid and electric vehicles, now favored in the market. This structural change profoundly modifies the nature of produced components and promotes innovation in green technologies.

Here is a table summarizing the direct impact of the CAFE standard on OEM strategies:

| CAFE Objective | Requirement for OEM | Industrial Consequence | Example of Adaptation |

|---|---|---|---|

| Reduction of average CO₂ emissions | Provide components for electric and hybrid vehicles | Conversion of production lines toward advanced electronics | Partnership with manufacturers of solid-state batteries |

| Reach a maximum threshold of 95 g CO₂/km | Improve energy efficiency of components | Research on light and recyclable materials | Development of parts made of recycled carbon fiber |

| Avoid financial penalties | Rapid adaptation of components and assemblies | Reduction of thermal models | Acceleration of electric model launches |

This ecological transition, combined with technological innovations, redefines the role and priorities of OEMs. They are no longer just manufacturers but become key players in industrial sustainability.

The target is clear: to avoid heavy financial penalties, OEMs must support manufacturers in producing hybrid and electric vehicles, now favored in the market. This structural change profoundly modifies the nature of produced components and promotes innovation in green technologies.

Here is a table summarizing the direct impact of the CAFE standard on OEM strategies:

| CAFE Objective | Requirement for OEM | Industrial Consequence | Example of Adaptation |

|---|---|---|---|

| Reduction of average CO₂ emissions | Provide components for electric and hybrid vehicles | Conversion of production lines toward advanced electronics | Partnership with manufacturers of solid-state batteries |

| Reach a maximum threshold of 95 g CO₂/km | Improve energy efficiency of components | Research on light and recyclable materials | Development of parts made of recycled carbon fiber |

| Avoid financial penalties | Rapid adaptation of components and assemblies | Reduction of thermal models | Acceleration of electric model launches |

This ecological transition, combined with technological innovations, redefines the role and priorities of OEMs. They are no longer just manufacturers but become key players in industrial sustainability.