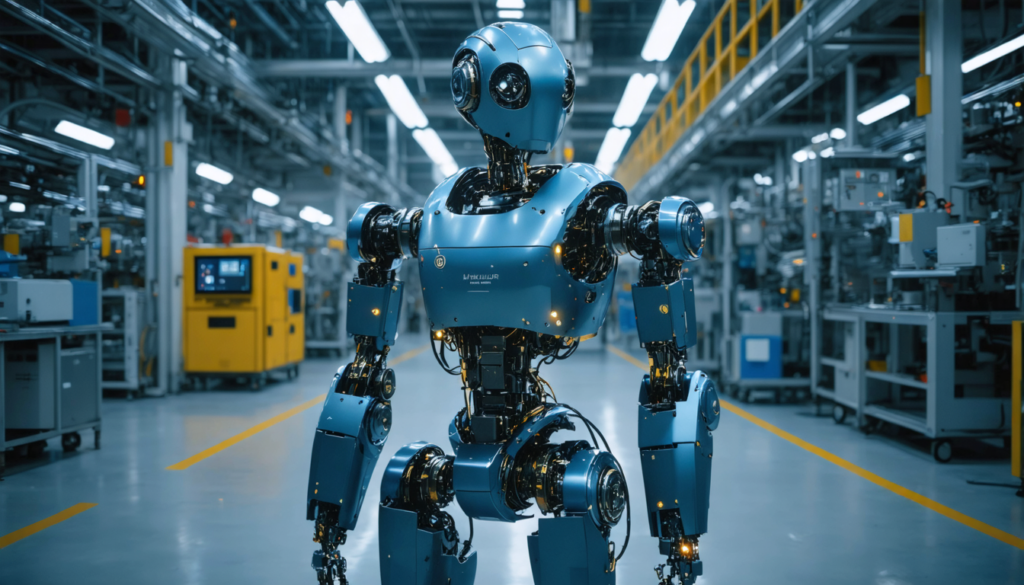

At the dawn of 2026, industrial robotics is experiencing a major revolution embodied by Atlas, the famous humanoid robot from Boston Dynamics. After years of development, it definitively leaves hydraulic technology behind to adopt a fully electric motor, marking an unprecedented technological advance. More than a mere prototype, Atlas becomes a true symbol of innovation and mobility in the smart factories proliferating around the globe. This technical transition plays a key role in the advanced automation of industrial tasks, promising increased productivity and seamless integration into human processes.

Startups and multinationals alike are all interested in this innovation that now goes beyond just demonstrating mechanical prowess. This agile robot, capable of complex movements, raises the challenge of peaceful coexistence between humans and machines on production lines. Its streamlined silhouette, now freed from bulky hydraulics, offers a new perception of robotics, where the combination of design and electric performance paves the way for a more sustainable, quieter, and more efficient industry. Let us explore together the multiple facets of this major breakthrough by examining the technical aspects, industrial applications, and future prospects of Atlas.

- 1 Who is Atlas from Boston Dynamics: a humanoid robot that has become an icon of electric robotics

- 2 Mechanical architecture and innovations in Atlas Boston Dynamics mobility

- 3 Intelligent sensors and artificial intelligence at the heart of Atlas’s perception

- 4 Industrial applications: Atlas Boston Dynamics at the service of intelligent automation

- 5 Other Boston Dynamics robots and their complementarity with Atlas

- 6 Atlas Boston Dynamics facing the competition: a rapidly growing and highly innovative market

- 7 Key technical characteristics of Atlas Boston Dynamics in a summary table

- 8 Importance of electric automation and future prospects for Atlas

Who is Atlas from Boston Dynamics: a humanoid robot that has become an icon of electric robotics

Atlas, developed by Boston Dynamics, is much more than a simple robot: it has become over the years a true legend in the field of humanoid robotics. Initially designed with complex hydraulic technology, this robot distinguished itself by its exceptional ability to perform parkour, run, jump, and execute human movements with remarkable agility. However, this first hydraulic generation had certain limitations for intensive industrial operation in real conditions.

In 2026, Boston Dynamics unveiled a new electrified version of Atlas that disrupts standards. From now on, all mechanical systems are based on high-performance electric motors, allowing for a lighter and more robust structure. This evolution frees the robot from constraints related to fluid leaks and noise generated by hydraulic cylinders, thus improving its integration into sensitive industrial environments. This new architecture accelerates Atlas’s transition from a laboratory prototype to a reliable machine ready to be massively deployed in automation factories.

The 2026 Atlas has fifty-six mechanical degrees of freedom, offering movements with physical capabilities that now surpass those of the human body. This joint freedom, combined with a streamlined design, facilitates maintenance and repair, while reducing breakdown risks. As a result, Atlas becomes not only a technical feat but also an accessible industrial tool, ready to enter a wide range of economic sectors. This approach perfectly illustrates how Boston Dynamics is transforming the vision of humanoid robotics, moving from a style exercise to a central player in smart factories.

Mechanical architecture and innovations in Atlas Boston Dynamics mobility

The shift from hydraulics to electric at Atlas is not limited to a simple change of motorization but embodies a real qualitative leap in the design of robotic mobility. Every joint of the robot is now equipped with high-performance electric actuators, capable of delivering significant torque while remaining compact. This technology allows for impressive movement fluidity: Atlas performs ground recoveries, full flexions, and handles objects with an almost biological suppleness.

This mechanical power and finesse of movements are due to several key innovations:

- Compact and powerful actuators: They surpass market standards in terms of power per unit of weight.

- Independent joint system: No restrictive wiring offering total freedom of movement.

- Lightweight and robust structure: Less than one hundred kilograms in total, optimizing battery consumption.

- Removable batteries and autonomy: Up to eight consecutive hours of operation without recharging, with rapid charging capability on automatic stations.

For example, Atlas can lift loads of up to thirty kilos per arm and reach a vertical range of about 2.30 meters, thus exceeding the usual capabilities of industrial robots. These abilities open the way to a multitude of applications, especially in complex handling, logistics, or interventions in accident-prone areas.

The lightness of the structure also helps improve safety in workshops by minimizing the risks of falls or shocks when moving on slippery floors. The chassis, made with composite materials, benefits from shielding against electrical interference, ensuring increased longevity and resistance to environmental hazards. This simplified mechanical architecture profoundly changes the relationship between machines and their environment, making robots more adaptive and durable.

Intelligent sensors and artificial intelligence at the heart of Atlas’s perception

Atlas would be nothing without its ability to perceive and understand its environment precisely. The combination of sophisticated sensors and artificial intelligence makes this robot an intelligent automation platform capable of operating autonomously in dynamic industrial environments.

Atlas’s perception system relies on highly efficient depth sensors that provide real-time three-dimensional vision. These sensors allow Atlas to observe each element of the factory precisely, whether it is an object on an assembly line or an unexpected obstacle in its path.

The data is then processed by NVIDIA Blackwell and Jetson Thor processors, specialized in machine learning and computer vision. Thanks to these computing units, the robot can anticipate human personnel movements, avoid obstacles with minimized latency, while adapting its gestures to handle delicate components thanks to its hands equipped with tactile sensors.

This collaborative sensory intelligence is reinforced by an advanced software system that synchronizes Atlas’s movements with the production flow, ensuring safe interaction with workers. Data transmission occurs privately via an encrypted internal network, protecting the confidentiality of sensitive factory information.

Dynamic mapping is another asset, generating a real-time image of movements and readjusting the robot’s paths as the factory layout evolves, a crucial functionality in constantly changing workspaces.

Industrial applications: Atlas Boston Dynamics at the service of intelligent automation

Atlas is now establishing itself in various industrial sectors thanks to its unprecedented performance. The automotive sector, notably with Hyundai Motor in Georgia, perfectly illustrates this integration. In this pilot factory, Atlas is used to sort, transport, and handle spare parts with precision and speed that exceed traditional human capabilities without causing fatigue or accidents.

This success opens the door to broader applications:

- Logistics and handling: handling heavy loads in automated warehouses, replacing rigid conveyors with flexible robots.

- Operations in complex environments: rescue missions in hazardous or cluttered environments, debris crossing.

- Agri-food industry: strict compliance with hygiene standards thanks to the IP67 sealed chassis and components resistant to water splashes.

- Continuous production: 24/7 cycle work thanks to rapid battery changes and robust units.

The robot integrates into a productive chain by communicating with the central management system, thus optimizing operation synchronization and flow forecasting. These advances contribute to more human-centered automation, where the robot complements humans in tedious and repetitive tasks.

Other Boston Dynamics robots and their complementarity with Atlas

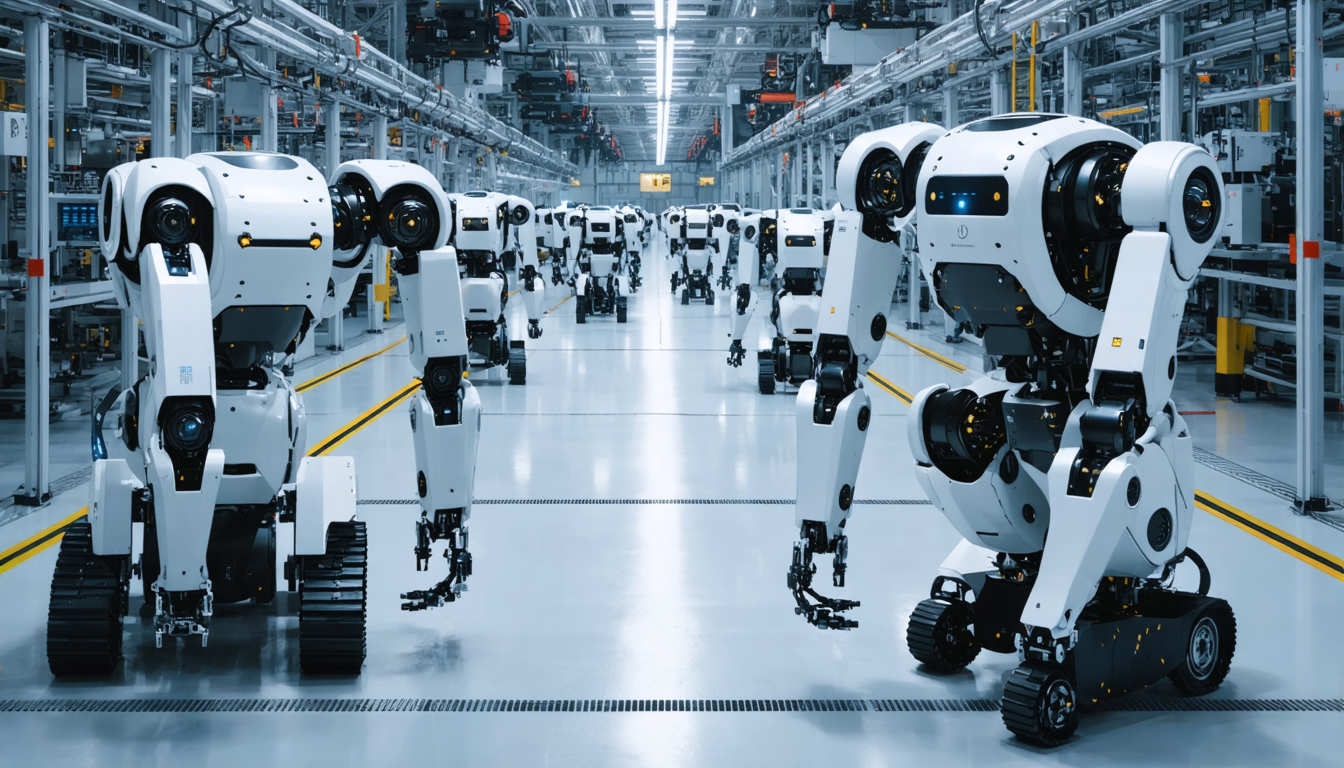

Boston Dynamics is not limited to Atlas. Its extended range includes other machines designed for different industrial niches, forming a complete automation ecosystem.

For example, Spot, the quadruped robot, benefits from a major update with the addition of new thermal sensors. It is specialized in autonomous infrastructure monitoring, capable of detecting electrical anomalies and transmitting its data in real time to a control team or to Atlas robots via the Orbit software. This synergy enables centralized and efficient site intervention management.

Another example, Stretch, a mobile-based handling robot, impresses with its ability to unload more than a thousand boxes per hour in logistics warehouses. Thanks to its enhanced mobility and articulated arm, it complements Atlas by handling bulky and repetitive loads, freeing Atlas for tasks requiring greater finesse.

A new project, Mobi, is also underway to address the needs of transporting loads over longer distances within industrial sites.

This diversity allows Boston Dynamics to offer a modular solution where robots exchange experiences and data, thus optimizing their collective intelligence. Shared learning accelerates progress and enriches individual capabilities.

Atlas Boston Dynamics facing the competition: a rapidly growing and highly innovative market

In a few years, the humanoid robot market has experienced exponential growth, attracting numerous players ready to compete with Boston Dynamics. Among notable competitors are Tesla with its third-generation Optimus, designed to integrate perfectly with its autonomous vehicles. Figure AI also offers the 02 model, while Apptronik emphasizes the ergonomics of its Apollo robot.

We also note the emergence of manufacturers like Unitree Robotics, which favors low-cost or rental solutions, thus facilitating access for small and medium enterprises. To establish themselves, each player works on their technical standards and innovations in perception and mobility.

In this context, Atlas maintains its advantage thanks to:

- Its advanced complex movement capabilities, especially on difficult terrain.

- Its versatility, enabling adaptation to different industrial environments.

- A software platform regularly updated, ensuring lasting competitiveness.

- Its robust and IP67 certified chassis, guaranteeing use in varied environments.

Massive investments in industrial robotics reinforce this dynamic, promoting the standardization of safety protocols and the creation of global distribution networks. This evolution contributes to the rapid transition of factories towards complete and agile automation.

Key technical characteristics of Atlas Boston Dynamics in a summary table

| Characteristic | Description | Advantage |

|---|---|---|

| Total weight | 89 kg with battery | Light for maneuverability and safety |

| Height | 1.90 meters | Human silhouette facilitating integration |

| Degrees of freedom | 56 movable joints | Precision and smoothness of movements |

| Lifting capacity | 50 kg payload | Handling of heavy objects |

| Autonomy | 8 hours of continuous operation | Long-duration operation without interruption |

| Environmental certification | IP67 (dust and water) | Robust in demanding industrial environments |

| Motor type | High-performance electric actuators | Fluid mobility and reduced size |

Importance of electric automation and future prospects for Atlas

The adoption of regenerative electric motorization in Atlas represents a pivotal step in the evolution of industrial robots. It meets both environmental and industrial needs by drastically reducing noise pollution and pollution related to hydraulic fluids. In an ecological transition context, this innovation allows for the design of cleaner factories where coexistence between humans and robots is harmonious.

Moreover, this technology opens the door to evolving mobile robotics, ready to integrate into intelligent digital ecosystems based on advanced artificial intelligence. This maximizes production line yield and offers better flexibility to respond to fluctuating demands. Interoperability with other Boston Dynamics robots, as well as third-party automation systems, highlights the integration towards a fully connected Industry 4.0.

Finally, it is likely that advances on Atlas will inspire other sectors, from rescue in accident-prone terrain to domestic assistance, including handling in hazardous environments or exploration. Electrified robotics, made more accessible and robust, now appears as an essential vector for industrial modernization worldwide.